Our Products

Product Name: pulper system

Product Code: CHB011

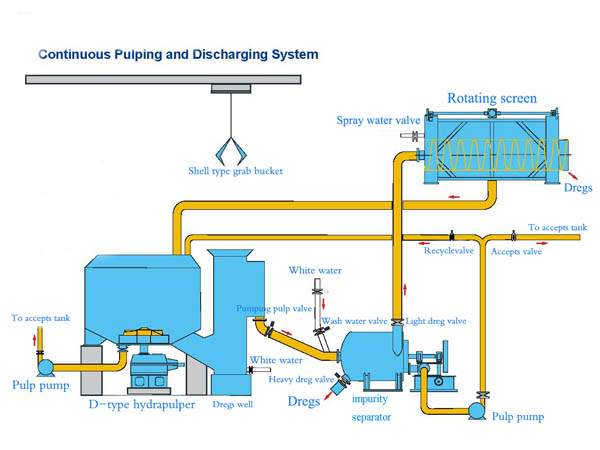

The pulper (equipped with dreg well, but not pulp level box) together with hydrapurger, rotary screen, ragger, grab bucket compose a continuous pulping and discharging system, to handle AOCC or OCC. This system makes the plastic, styrene foam and other light and heavy impurities removed out from the hydrapulper before they are broken into little ones that can pass through hydrapulper screen plate.

The working description is: after normal working of the hydrapulper, the larger or long and narrow light rejects are removed out by the ragger. Other light and heavy rejects in the cell body and part of the pulp are discharged into the dreg well continuously. The washing water in the entrance of the dreg well can wash the accept pulp fiber back into the hydrapulper, at the same time not stop other rejects coming into the dreg well. In the dreg well, the heavy rejects sink into the bottom by gravity and are discharged by reject discharging window regularly; the large chunk of light rejects are grabbed and discharged by the shell-type grab bucket on the top of the dreg well. Other light rejects and pulp are extracted by hydrapurger regularly from the dreg well, to recover accept pulp and to discharge rejects. This system has the following features:

1. The light and heavy rejects are removed out directly from hydrapulper before they are beaten broken, which can lighten the work load of the latter purification and screening equipments, and improve equipment working condition.

2. The pulping rate of the waste paper after hydrapulper is 70%. The pulp and rejects that are not broken are secondary broken and separated by hydrapurger.

3. The screen hole diameter of hydrapulper can be enlarged properly to reduce pulping time, and to improve hydrpulper capacity of production.

4. It can effectively avoid severe damage to hydrapulper rotor, blade and screen plate by hard heavy rejects as metal block,

stone and etc.

5. The removing rate of the plastic, styrene foam, stickies can reach more than 70%, and fiber loss is few.

6. The high efficiency running of each equipment can increase the capacity of each equipment relatively, and reduce power consumption, and can also reduce the machine stop time for cleaning.

7. This system can adopt programmable logic controller, to realize automatic control, to reduce operation fault, to reduce running cost and improve pulp quality.